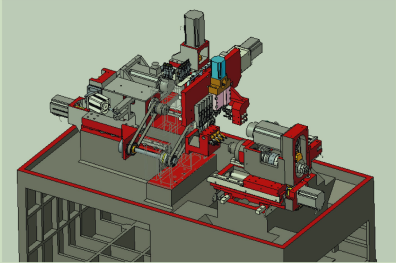

B13 dual-spindle CNC lathe features turning and milling composite processing capabilities, this high-precision, versatile, and highly practical machining equipment is suitable for large-scale, multi-variant, and high-precision processing tasks involving elongated parts with significant length-to-diameter ratios, as well as small and irregularly shaped components. The machine's wide processing range makes it ideal for various industries, such as medical, aerospace, defense, automotive, motorcycle, telecommunications, refrigeration, optics, home appliances, microelectronics, electronics, timepieces, mobile phones, and more. It is designed for the composite processing of high-precision, large-quantity, and complex-shaped shaft components, along with intricate and small precision parts.

●Employing the sub-spindle and rear tool post, the CNC machine enables simultaneous front and back machining operations.

●Equipped with a 3-axis transverse power head, transverse rigid tapping, front-facing rigid tapping, and rear-facing rigid tapping.

●By adjusting the chuck using the clamping force of the main spindle and sub-spindle, it is easy to grip delicate and precise components.

●With high-speed angular cooling, this machine provides more uniform heat dissipation and improved performance compared to conventional air cooling. It employs an absolute positioning system, eliminating the need to return to the origin when switching on or off, saving time, effort, and labor. The machine operates with high efficiency and minimal manual labor for 24 hours without requiring power reset.

●Using a fixed guide bushing and linked guide bushing results in better efficiency and makes it highly suitable for high-precision machining.

|

机床参数 |

|||||

|

电源 |

电源额定电压 |

三相交流380V |

行程 |

X2轴行程 |

380mm(直径量) |

|

|

电源额定频率 |

50HZ |

Z2轴行程 |

160mm |

|

|

|

总输入功率 |

10kW |

X2轴伺服马达功率 |

1kW |

|

|

数控系统 |

宝元 |

T6850 |

Z2轴伺服马达功率 |

1kW |

|

|

最小设定单位 |

0.001mm |

冷却系统 |

切削油用电机功率 |

0.48kW |

|

|

X轴脉冲当量 |

0.0005mm |

冷却箱容量 |

150L |

||

|

Z轴脉冲当量 |

0.001mm |

润滑系统 |

马达功率 |

25W |

|

|

切削速度 |

1-4000mm/min |

容量 |

1.5L |

||

|

X轴快速进给速度 |

15000mm/min |

主轴刀具 |

10*10方刀+∮16孔刀 |

5把+4把 |

|

|

Y轴快速进给速度 |

15000mm/min |

副轴刀具 |

∮16孔刀 |

4把 |

|

|

Z轴快速进给速度 |

15000mm/min |

机床尺寸 |

长*宽*高 |

2030*1360*1960 |

|

|

主轴 |

最大棒料直径 |

Φ13mm |

|

机床重量 |

1700KG |

|

主轴通孔直径 |

Φ14mm |

可选配置 |

|||

|

主轴中心离地面高度 |

1010mm |

||||

|

主轴转速 |

0-5000r/min |

主轴加侧面动力头 |

夹头ER11 |

3把 |

|

|

主轴马达功率 |

2kW |

功率 |

0.4kW |

||

|

副轴 |

最大夹紧直径 |

Φ13mm |

转速 |

4000r/min |

|

|

副轴转速 |

0-5000r/min |

旋转中心架 |

加旋转中心架后Z轴行程 |

100mm |

|

|

副轴马达功率 |

2kW |

||||

|

行程 |

X1轴行程 |

60mm(直径量) |

|

|

|

|

Y1轴行程 |

230mm |

|

|

|

|

|

Z1轴行程 |

150mm |

|

|

|

|

|

X1轴伺服马达功率 |

0.75kW |

|

|

|

|

|

Y1轴伺服马达功率 |

1kW |

|

|

|

|

|

Z1轴伺服马达功率 |

1kW |

|

|

|

|

|

滑轨形式 |

直线导轨 |

|

|

|

|

|

机床配置 |

||

|

名称 |

型号/规格 |

厂家 |

|

系统 |

宝元 |

台湾 |

|

主轴 |

国产 |

自制 |

|

X1轴电机 |

0.75kW绝对值伺服电机 |

汇川+总线 |

|

Y1轴电机 |

1kW绝对值伺服电机 |

汇川+总线 |

|

Z1轴电机 |

1kW绝对值伺服电机 |

汇川+总线 |

|

X2轴电机 |

1kW绝对值伺服电机 |

汇川+总线 |

|

Z2轴电机 |

1kW绝对值伺服电机 |

汇川+总线 |

|

丝杆 |

|

上银/银泰 |

|

导轨 |

|

上银/银泰 |

|

|

|

|

|

|

|

|

|

|

||

Main business:CNC machine tools, automated production lines, industrial robots